We strive to use our skills and experience in Building Information Management to help our customers meet their project goals. Mechanical & Electrical layout for concrete decks and BIM modeling are our specialties.

Whether you need M&E deck layout, drawings of equipment locations, or post-project as-builts, our staff will get it done.

With our Trimble layout tool we will survey your decks, locating your cans, sleeves, penetrations and all other equipment on the deck to within 2mm on average. In addition to reducing your layout costs, we free up your skilled labour so you can make progress on other parts of the project.

Once we have accurately located your equipment, we create and maintain an electronic record for five years that proves your equipment was laid out accurately. No more coring or chipping concrete because another trade kicked your can or sleeve over.

Based on South Vancouver Island in Victoria, you can rely on our team of experienced BIM modelers and field staff for your construction projects.

Traditional methods require workers to kneel on decks and manually measure the location of points. This requires more time and people than using a layout tool, and can be inaccurate.

Decks are messy and can be covered in garbage or construction materials which slows down traditional deck layout.

There’s often not enough time given on decks. The next part of the building process is often on its way (rebar). The speed of our process can alleviate that time pressure.

Its faster: we layout, on average a point every 90 seconds.

Its more accurate: we can lay out points within, on average, 2mm of their position on the drawings

It takes less workers: in a time of labour shortages, we can free up your skilled labour.

It reduces your costs: by laying out your decks faster and with less people, you save money. We aim to significantly cut our customer’s layout costs.

There is a digital record: if there is any question later on if points were accurately laid out, there is a digital record of all points that can be used to settle disputes.

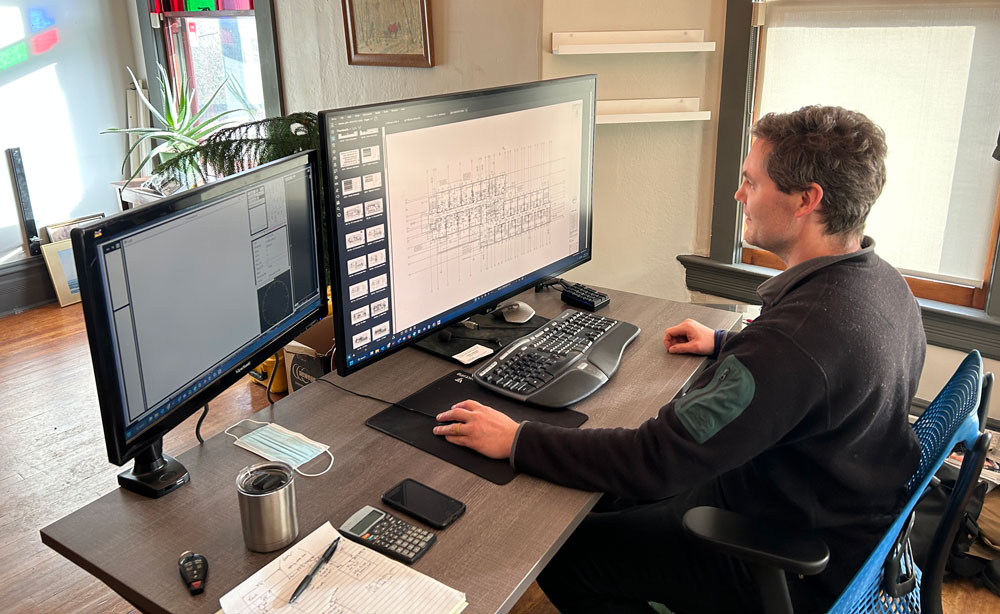

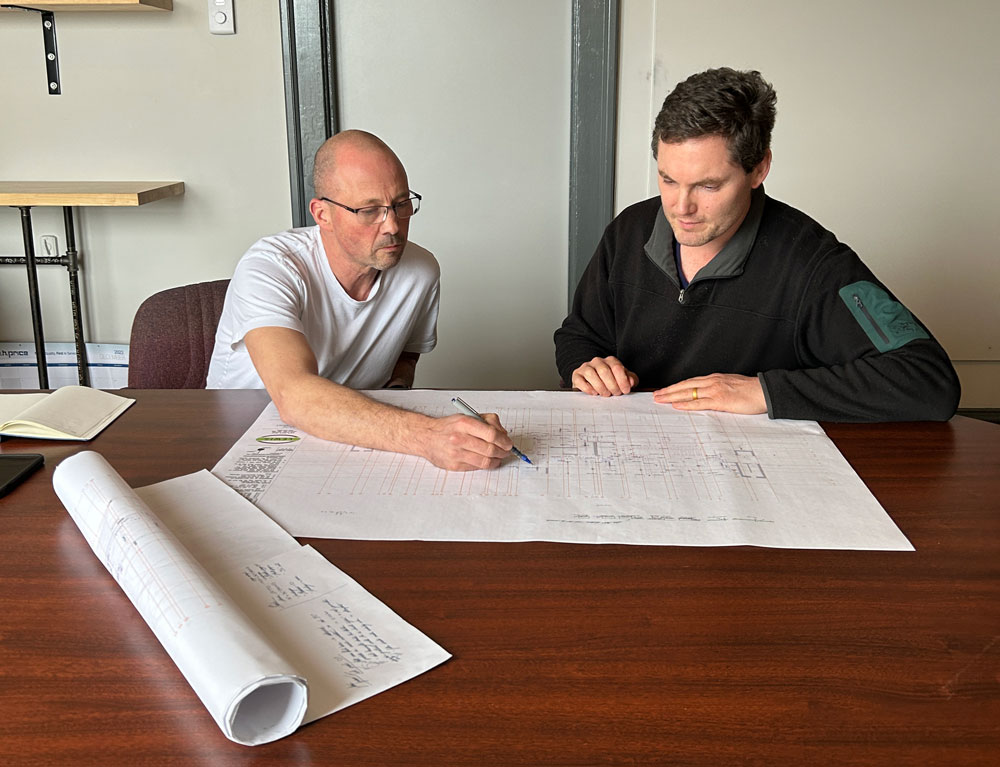

We take the drawing packages and CAD files provided by the consultant and use them to create a digital footprint of your ideal deck layout. We all know that the drawing packages are diagrammatic in nature, so, with input from your site foreman, we mark the deck in a way that works for you.

We set up our Robotic Layout Tool off the gridlines on the deck. Then we locate your points and mark their locations, so your crew knows exactly where and what is placed on the deck. Once we are finished, we confirm the locations with your site crew. We don’t leave until you know everything has been marked out in the right place.

We stand behind our work. Once we are back in the office, we produce a report that shows the exact locations of all your points. We will store this report for you in case your customer raises a dispute with you later. Layout reports and produced drawings are available upon request for 5 years.